Inventory Management

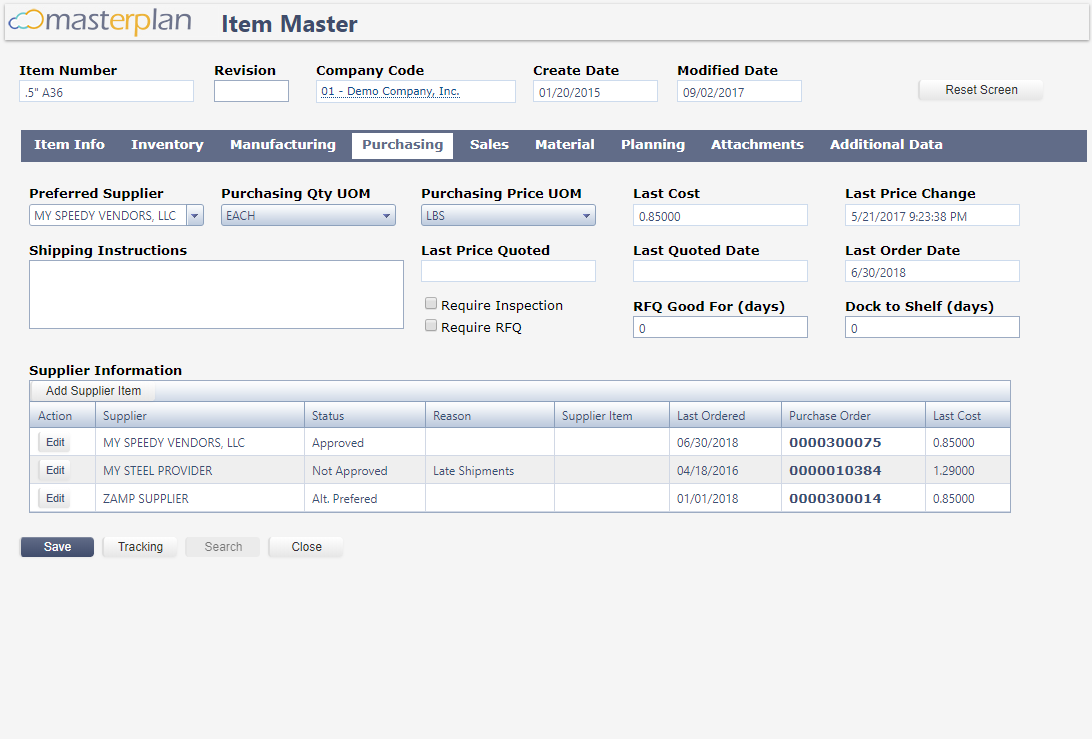

Keep your inventory costs to a minimum. Track inventory consumption and analyze potential problems. Detailed procurement history enables you to track cost, lead time and quality information. Raw material and finished goods labels can be generated for traceability.

Bill of Materials

Multi-level and phantom bill of materials can be created. Exploded BOM view displays the items at all levels.

Cycle Counts

Cycle counts can be setup based on time or usage intervals. Alerts can be setup to notify when a cycle count should occur.

Pick, Pack and Ship

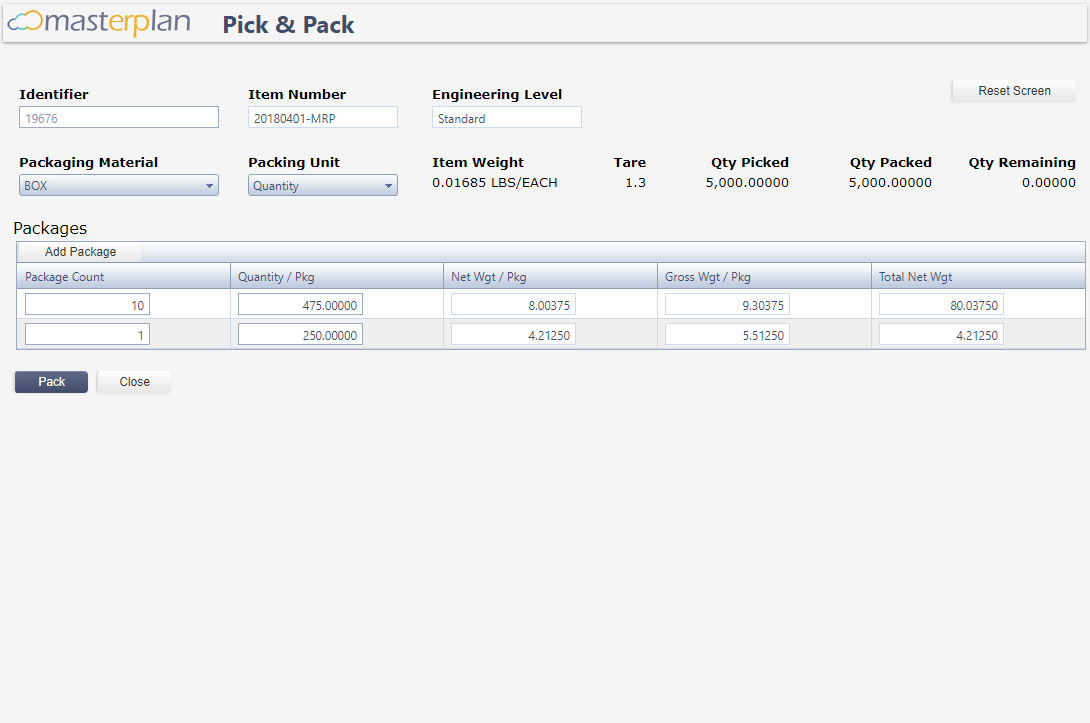

Inventory can be packed prior to shipping or during. Barcode labels for each packaging material are generated for proper tracking. When shipping, simply scan the barcode labels for accurate picking.

Planning

The MRP functionality is integrated with the inventory module. Items can be setup per MRP Controller and also planning method. This data feeds the MRP Workbench, order recommendations and also available-to-promise functions.

Recipe Setup

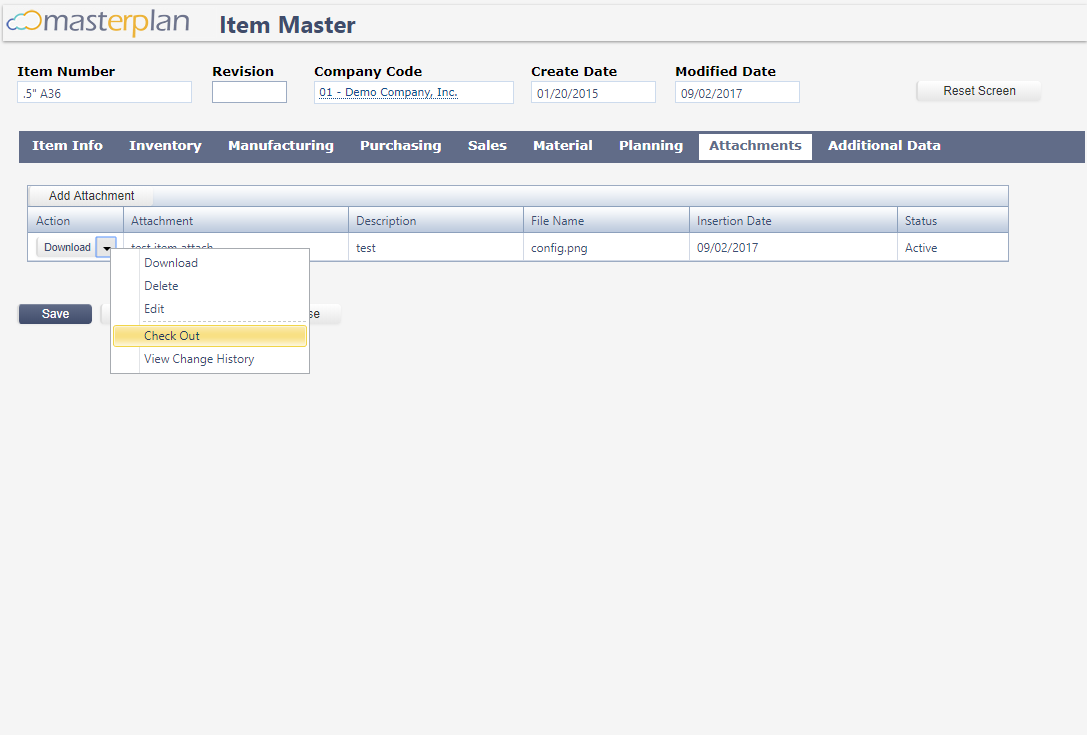

Master recipes of ingredients can be configured for batch process manufacturing. Store the supporting documents with the item using the check in/out functionality.

Replenish Methods

Inventory can be replenished by setting up planned purchase intervals, minimum stock levels. Items can be purchased or manufactured per order.

Traceability

Inventory can be tracked down to the detail that you need. Lot, serial, heat number and expiration dates can easly be tracked.

Contact us today to learn more.

Thank you for giving us the opportunity to demonstrate how we can help your company increase productivity and lower costs.