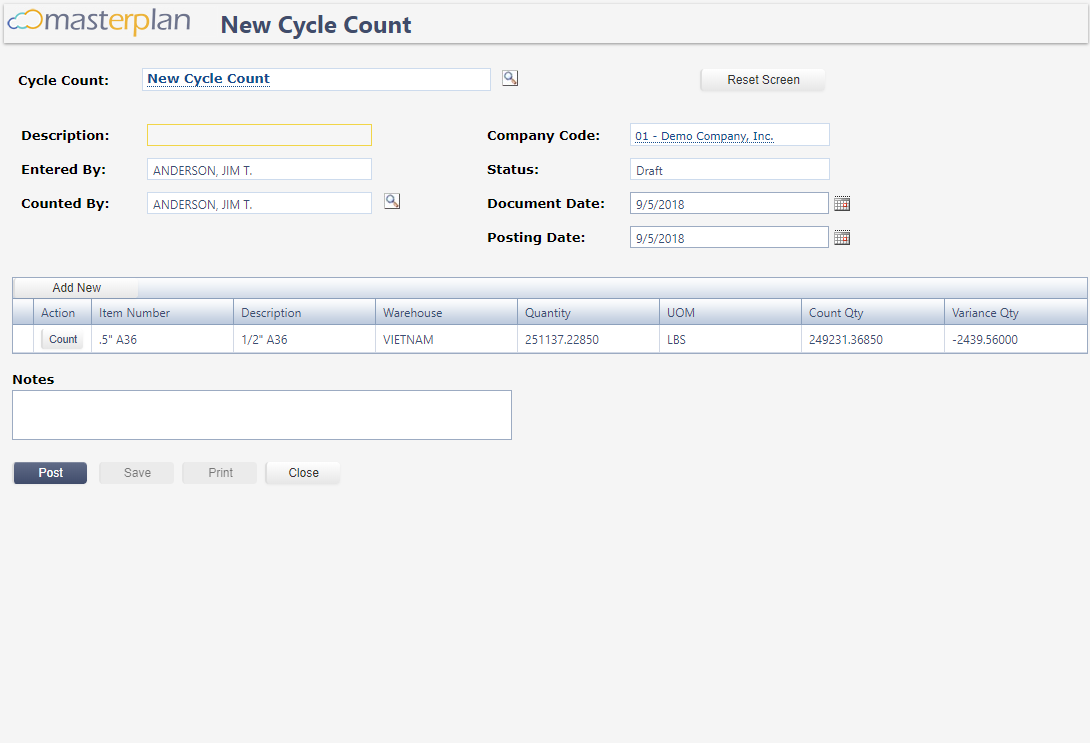

Material Management

Manage all aspects of your raw material throughout your product life-cycle. Barcode labels can be generated for each piece of material to give you accurate inventory counts and traceability.

Dimensional Inventory

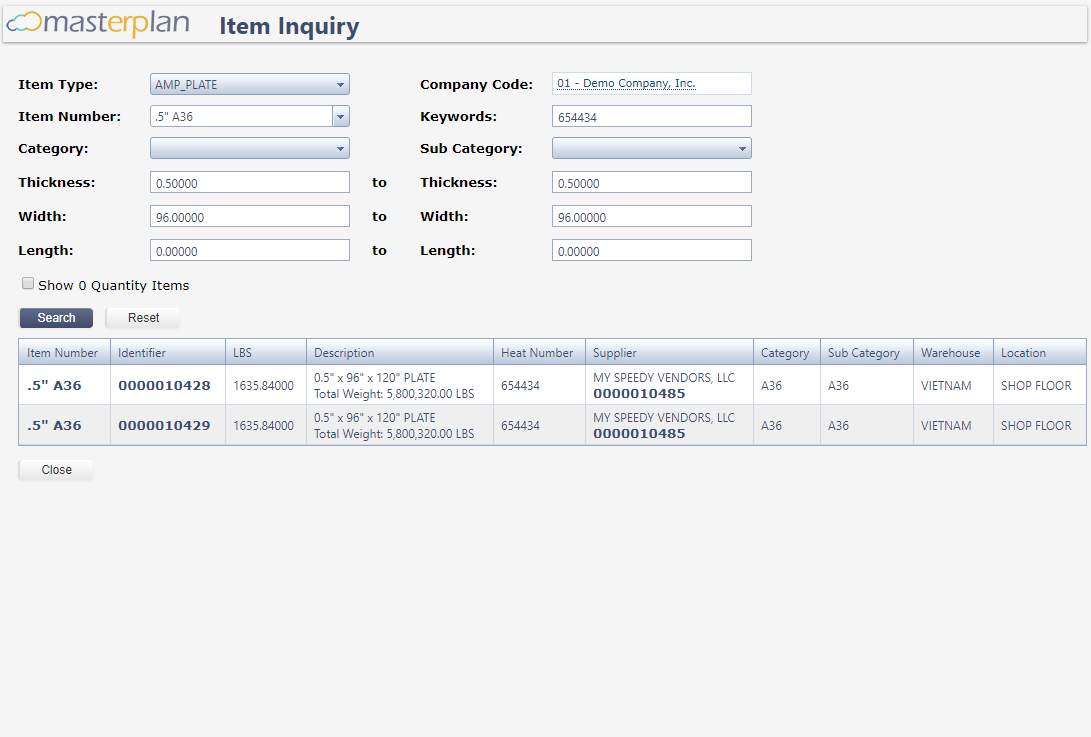

Raw material can be purchased and stocked using multiple units of measure. You can track each piece of material and its dimensions. For sheet material, you are to store multiple dimensions to account for the remaining shape after cutting.

Cert / MTR Tracking

Material certs can be attached to each raw material item. Certs can be retrieved at any step in the manufacturing process.

Material Drops

Raw material drops can be tracked within the system. When allocating raw material to a job, the system will return the drop back into inventory.

MRP Integration

Material tracking is integrated with the MRP Workbench. When the MRP runs, it checks all requirements for material and allows those items to be combined on one purchase order.

Smartphones and handhelds

While on the shop floor, you can use your smartphone, handheld scanner or tablet to make raw material transactions and look up current stock.

Traceability

Heat numbers are tracked from the initial goods receipt throughout the whole manufacturing process. Reports can be generated to find out what production orders used specific heat numbers, when and where you ordered the material from. Electronic material certs can be attached to each material item.

Contact us today to learn more.

Thank you for giving us the opportunity to demonstrate how we can help your company increase productivity and lower costs.