Material Requirements Planning

Plan your material needs to fulfill current demand and look ahead based on forecasts. Item planning methods can be setup different ways depending on your business requirements. The MRP Workbench is used to query the requirements based on certain criteria.

Exceptions

View the different exceptions that have occurred with inventory levels. Some of the alerts are items with shortage, items with excess inventory, items with expired lots, production and sales orders past due.

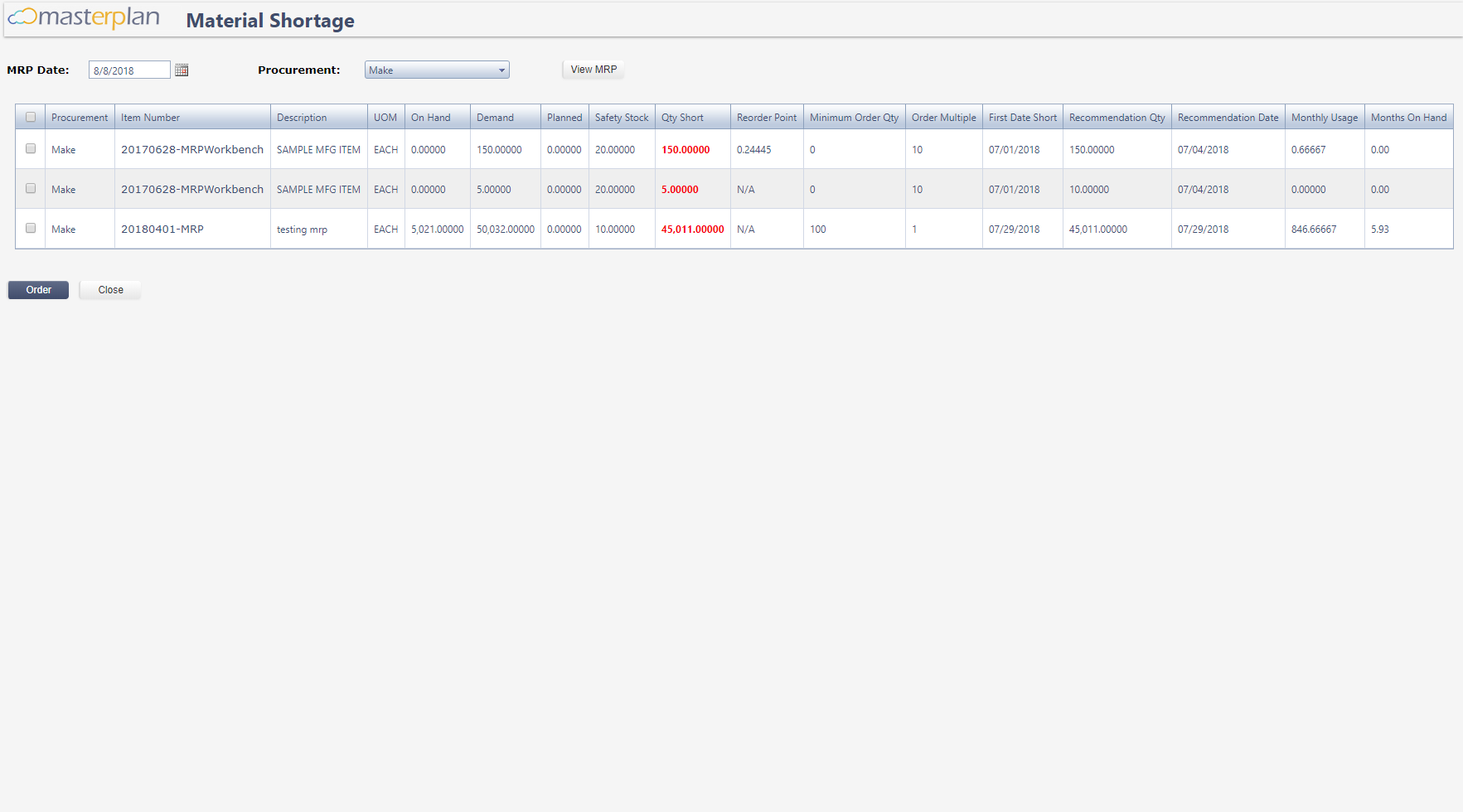

Material Shortage

View items that need to be ordered or manufactured. You can easily see how many are on-hand, what the demand is and what quantities are currently planned.

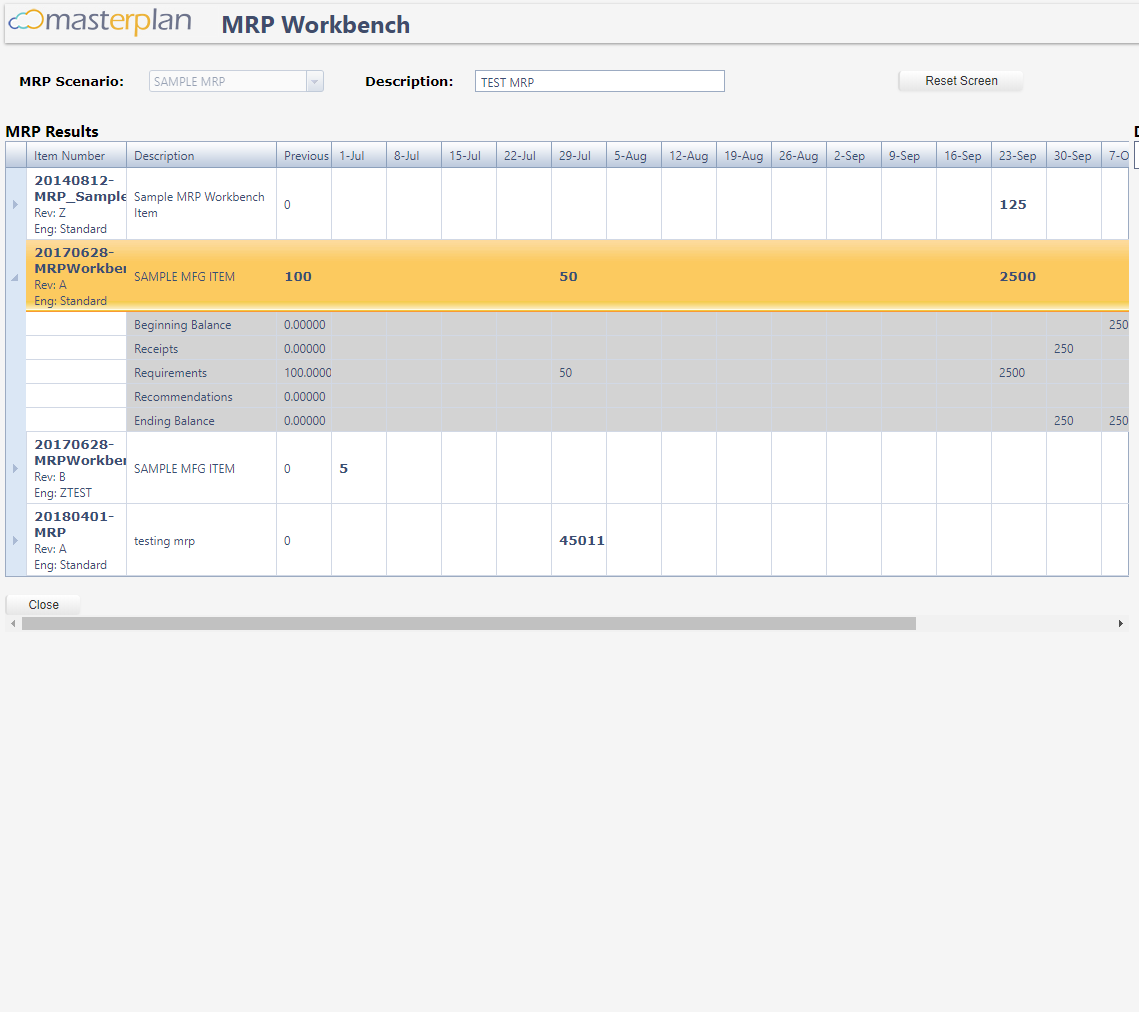

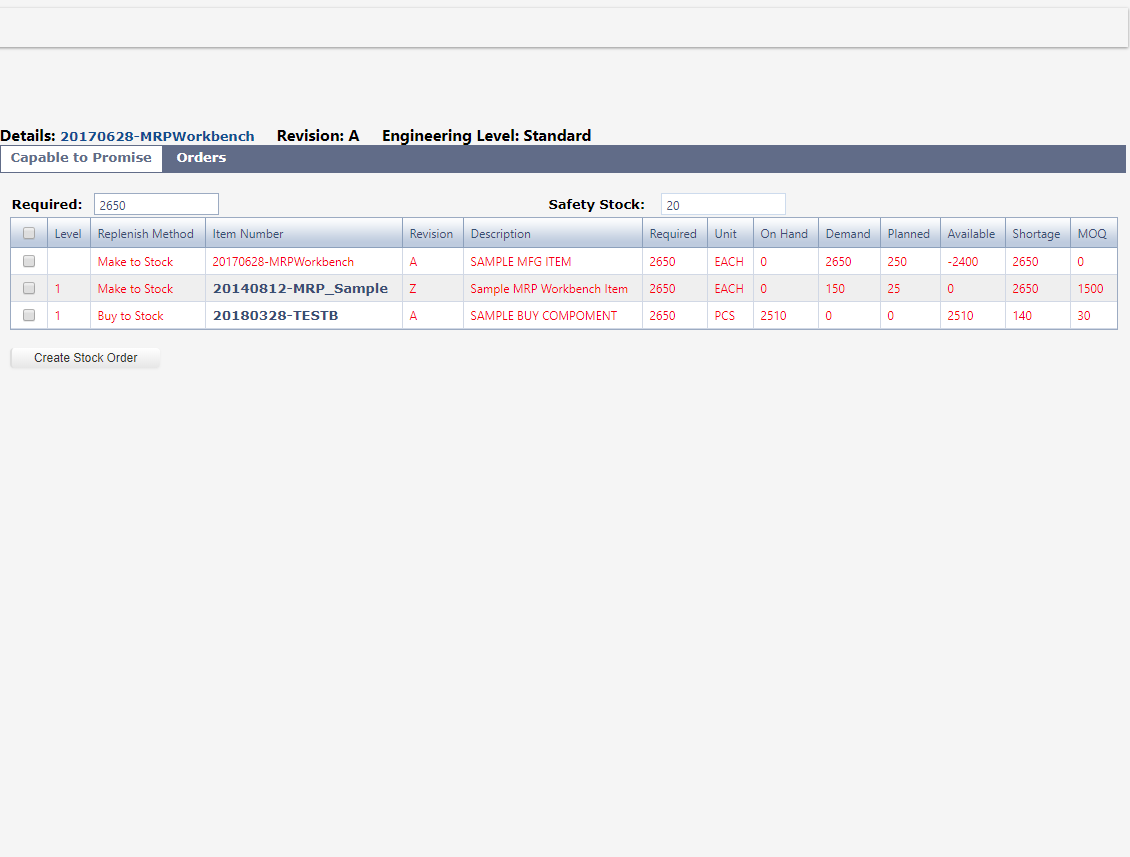

MRP Workbench

The MRP Workbench is a planning tool that allows you to identify and take the proper action on the material shortages. The horizontal view shows each bucket and the quantity short. Drill into the buckets to see what orders are creating the demand. Adjust due dates and create stock orders from the MRP Workbench.

Recommendations

Order recommendations are a result of the MRP Workbench or an automatic MRP run. These recommendations can be easily converted to a production or purchase order depending on the procurement type.

Contact us today to learn more.

Thank you for giving us the opportunity to demonstrate how we can help your company increase productivity and lower costs.