Gain visibility of your manufacturing operations

Masterplan Manufacturing is specifically for production order routing, scheduling, costing and tracking of each part manufactured on the shop floor. The parts can either be custom parts or production parts which can be sold as finished goods out of inventory. Masterplan Manufacturing gives managers the information needed to make critical decisions for their company. This information is based on data collection from each job on the shop floor. Easily track quantities completed, down time, inventory usage, scrap and rework.

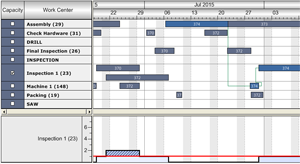

Capacity Planning

Drill down into the capacity of your work centers. Run what-if scenarios to determine how to make adjustments.

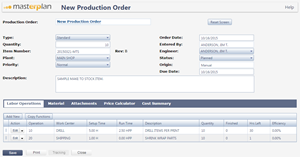

Production Orders

Production orders are generated from product demand. The demand can come from sales forecasts, sales orders and also sub assembly requirements from other production orders.

Scheduling

Production orders are scheduled based on the work centers capacity, company schedule and resource availability.

Make to Stock

Make to stock allows you to inventory the produced goods. Completed production orders are transfered to inventory and sales orders pull from that stock.

Make to Order

Make to order allows you to custom make items per order. This is a typical selection for job shops and custom manufacturers.

Paperless Shop Floor

The work center dispatch list alerts the user of the next job to run. Tablets can also be used on the shop floor to streamline operations.